Type |

No.

Of

Sheds |

âXâLength inches

(mm) |

Diameter

Inches

(mm) |

|

Leakage

Distance

Inches

(mm) |

Dry

Arc

Distance

inches

(mm) |

Lighting withstand voltage |

Wet power frequency voltage |

SML

Specified Mechanical Load(KN) |

|

|

|

|

|

|

|

|

|

|

D |

d |

|

|

|

|

|

FPQ-10/5.0 |

3 |

285 |

123 |

93 |

450 |

208 |

110 |

40 |

5.0 |

|

|

|

|

|

|

|

|

FPQ-24/10.0 |

5 |

320 |

168 |

/ |

800 |

206 |

170 |

70 |

10.0 |

|

|

|

|

|

|

|

|

FPQ-24/12.5 |

5 |

252 |

165 |

135 |

650 |

165 |

170 |

65 |

12.5 |

|

|

|

|

|

|

|

|

FPQ-36/12.0 |

14 |

480 |

130 |

115 |

1200 |

356 |

230 |

90 |

12.0 |

|

|

|

|

|

|

|

|

FPQ-36/10.0 |

11 |

507 |

132 |

122 |

1100 |

356 |

230 |

90 |

10.0 |

|

|

|

|

|

|

|

|

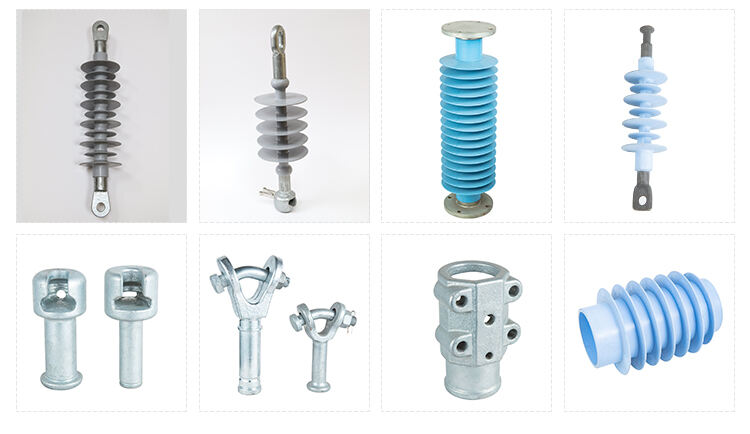

1. Shed connected with core by integral foring

2. The thinness of housing > 3mm, uniform to IEC Standard

3. Acid resistant, hight temperature resistant of epoxy fiberglass core

4. Metal end fittings, core and sheds connected by new crimping process

5. Hot galvanization and technology of rare earth aluminum coating to avoid coating shedding prolonging the service life

(1) Small volume, light weight, sheds have good elasticity, not broken, con venient transportation and installation, economy.

(2) High mechanical strength FRP ROD has high tensile strength, small size, light weight, high tensile strength.

(3) High antifouling property, good aging resistance performance, high anti pollution flashover voltage, good electric corrosion resistance.

(4) Easy installation, greatly reduce maintenance charges and manual labor intensity.

(5) Simple production process, short delivery time

Product characteristics

1. No flaw, crack in the surface and interior, each bar color uniform(green or light yellow).

2. Can withstand the sawing, milling, planning, drilling, lathe and other mechanical processing.

3. Internal thread can be tapping with screw tap, external thread can be polished, but not allowed to bear overload.

4. It has good damping, creep resistance, fatigue resistance, fracture resistance, high temperature resistance, stress corrosion resistance etc

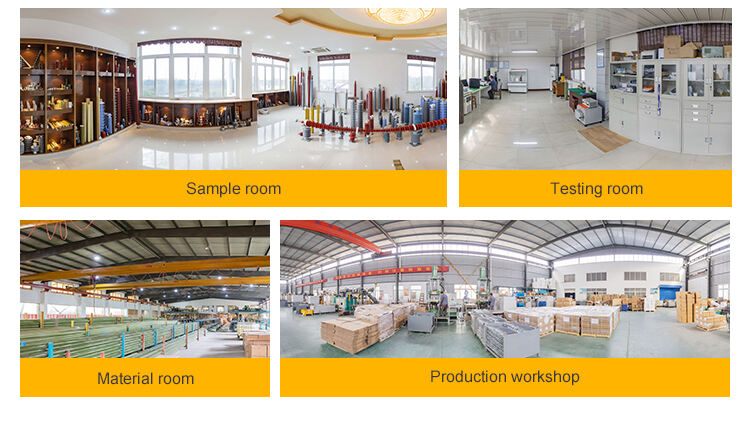

Taizhou HuaDong Insulated Material Co., Ltd (FORMER Yangzhou Dajieshi FRP products Co., Ltd) which was found in October in 1994. Our company is mainly engaged in the production of FRP ROD, profiles, related terminal parts and accessories products. The terminal and accessories products such as: various types of composite insulators, silicone rubber, insulator fittings, line fittings and so on. The epoxy fiberglass core we produce as intermediate connector and insulating parts is widely used in all the fields and many kinds of composite insulators production. The profiles and composite insulator are widely used in electric power, electronics, electric railway, construction, automotive and environmental protection field. THIM products are widely sales in North and South America, Africa, Asia, Europe etc such as USA, Kenya, Korea, India, Vietnam, Russia, Germany, Romania and other countries and vast areas in our country. THIM is becoming a well-known supplier for insulation products field in the global

Q1. Are you a manufacturer or trading company?

A. Manufacturer/ Trading Company

Q2. How do you make sure your good quality? A. We use the best raw material, and every single product will go through a series of strict test

Q3. Will you accept using customer's logo?

A. Yes, we can offer OEM and ODM

Q4. Can I order some sample for our testing?

A. Yes, of course

THIM

Introducing the latest addition to our products New Manufacturer Customized Pin Post Composite Pin Insulator. A game-changer in the electrical industry providing superior performance and reliability compared to traditional porcelain insulators.

Suitable for a variety of outdoor applications including pole-mounted transformers overhead lines and distribution networks. It is constructed of high-quality composite materials making it lightweight and easy to install.

Highly customizable allowing for tailored solutions to meet specific customer needs. We offer THIM a range of sizes and specifications ensuring that our composite pin insulator can handle a wide range of electrical load requirements.

At THIM we pride ourselves on the superior design and manufacturing of our products. Our composite pin insulator has been extensively tested and is compliant with industry standards ensuring its safety and reliability.

Offers significant benefits over traditional porcelain insulators. It has a higher strength-to-weight ratio making it more durable and resistant to breakage. It is more resistant to damage from environmental factors such as UV radiation and pollution ensuring a longer lifespan and less maintenance.

With excellent insulation resistance and low power loss. It has a higher creep age distance making it less prone to flashovers and electrical failures.

Installation is simple and fast reducing downtime and labor costs. Its lightweight design makes it easy to handle and maneuver during installation reducing the risk of accidents and injuries.

Get yours now.