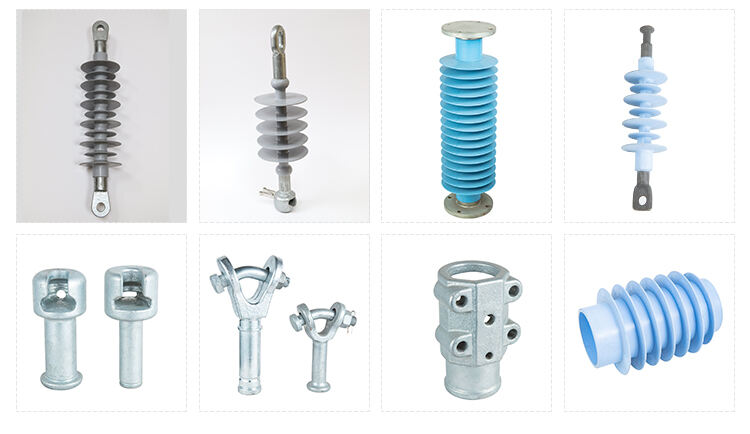

Linh kiện cách điệncomposite đường sắt điện khí hóa

Bộ phận cách điện đường sắt hợp kim Một tên khác: Bộ phận cách điện đường sắt, linh kiện điện của mạng tiếp xúc đường sắt, bộ phận cách điện hợp kim cho đường sắt điện khí hóa, bộ phận cách điện hợp kim cho đường sắt điện khí hóa có các ưu điểm như cấu trúc gọn gàng, tính toàn vẹn cao, khả năng chống bám bẩn tốt, trọng lượng nhẹ, kích thước nhỏ và đặc tính cách điện tốt, độ bền cơ học cao, không cần vệ sinh định kỳ, chủ yếu được sử dụng trong xây dựng đường sắt tốc độ cao và hệ thống giao thông đường sắt đô thị nhẹ, mang lại sự thuận tiện lớn cho việc lưu trữ, vận chuyển, lắp đặt, bảo trì. Tay đỡ sử dụng vật liệu hợp kim thép không gỉ, có hiệu suất chống ăn mòn vượt trội, giải quyết các vấn đề về độ ẩm của sản phẩm ăn mòn, mưa axit và các điều kiện thời tiết khác, có thể kéo dài đáng kể tuổi thọ của sản phẩm, cung cấp thiết bị đáng tin cậy để thực hiện xây dựng đường dây truyền tải gọn nhẹ.

Sản phẩm này phù hợp cho điều kiện vận hành trong hầm đường sắt điện hóa phức tạp, có thể hiệu quả ngăn ngừa sự cố phóng điện do ô nhiễm, giảm công việc vệ sinh và bảo trì. Do kích thước nhỏ, diện tích thông thủy của hầm nhỏ, không có sản phẩm thay thế bằng sứ hoặc kính cách điện.

|

|

|

Tải trọng cơ học định mức rơi

|

|

|

|

Điện áp chịu được xung chiếu sáng

kV

(đỉnh)

Không ít hơn

|

Điện áp chịu đựng tần số công nghiệp

(giá trị hiệu dụng)

Không ít hơn

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cấu trúc sản phẩm và ưu điểm

Công ty chúng tôi chuyên sản xuất bộ phận cách điện composite cho đường dây truyền tải điện. Cấu trúc quan trọng bao gồm vỏ chia tầng, lõi thủy tinh epoxy và phụ kiện kim loại đầu mút. Bề mặt của phụ kiện đầu mút được phủ lớp mạ kẽm (mạ kẽm nóng) để bảo vệ chống ăn mòn. So với các loại sứ và kính cách điện cùng loại, bộ phận cách điện bằng cao su silicone có những ưu điểm sau: (1) Thể tích nhỏ, trọng lượng nhẹ (chỉ bằng 1/7~1/10 so với bộ cách điện gốm ở cùng mức điện áp), các rãnh có tính đàn hồi tốt, không bị vỡ, thuận tiện cho vận chuyển và lắp đặt, kinh tế. (2) Độ bền cơ học cao. CỐT FRP có độ bền kéo cao, gấp 5-10 lần vật liệu gốm, do lõi có diện tích mặt cắt nhỏ, điều này làm cho sản phẩm có kích thước nhỏ, trọng lượng nhẹ, độ bền kéo cao, và dễ dàng sản xuất các bộ cách điện lớn hơn 300KN. (3) Tính chống bẩn cao, khả năng kháng lão hóa tốt, các rãnh được làm từ silicon rubber injection mold có tính chất khử nước và di chuyển tốt, điều này làm cho bộ cách điện có điện áp chống phóng điện bẩn cao và khả năng kháng ăn mòn điện tốt. (4) Dễ dàng lắp đặt và bảo trì, có thể giảm đáng kể thời gian ngừng hoạt động do bảo trì và chi phí bảo trì do cường độ lao động thủ công gây ra. (5) Quy trình sản xuất đơn giản, thời gian giao hàng ngắn.

Composite Electric Đường sắt Máy cách nhiệt

① Phần mái nối với lõi bằng phương pháp tạo hình tích hợp

② Phụ kiện kim loại, lõi và phần mái được kết nối bằng quy trình ép mới

③ Độ dày của vỏ > 3mm, độ dày đều, tuân thủ tiêu chuẩn IEC

④ Chống axit, chịu nhiệt cao của lõi sợi thủy tinh epoxy

⑤ Vật liệu của phụ kiện kim loại đầu mút sử dụng mạ kẽm nóng và công nghệ phủ nhôm đất hiếm để tránh bong tróc khi ép, kéo dài tuổi thọ của sản phẩm

cấu trúc sản phẩm

1. Vỏ lá chắn: Cao su silicon, polymer hợp chất

2. Lõi sợi thủy tinh epoxy: Thanhdây epoxy gia cường sợi thủy tinh

3. Chi tiết kim loại đầu mút: Thép mạ kẽm nóng

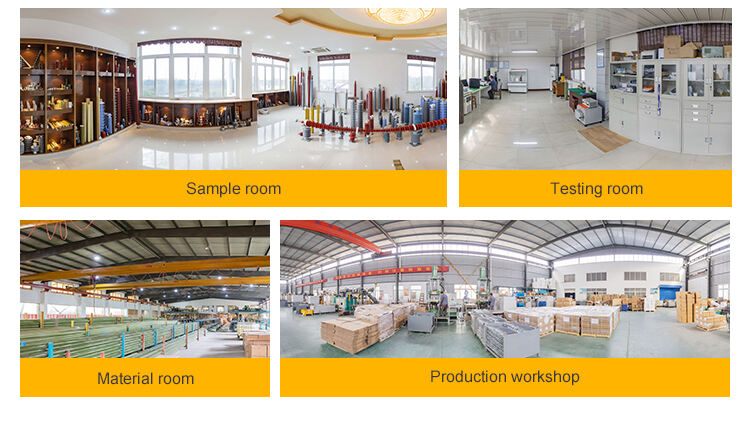

Thiết bị và dụng cụ kiểm tra cho絕縁 tử composite

Chúng tôi có hệ thống đảm bảo chất lượng nghiêm ngặt, thiết bị sản xuất và kiểm tra hàng đầu, cùng nhiều nhân sự kỹ thuật tài năng. Chất lượng sản phẩm của chúng tôi tuân thủ các tiêu chuẩn IEC, ISO, ASTM, ANSI, GB/T, Q/G-DW, JB/T, DL v.v.

Công ty TNHH Vật liệu Cách điện Taizhou HuaDong (trước đây là Công ty TNHH Sản phẩm FRP Yangzhou Dajieshi) được thành lập vào tháng 10 năm 1994. Công ty chúng tôi chủ yếu chuyên sản xuất các sản phẩm thanh FRP, profile, các bộ phận đầu cuối và phụ kiện liên quan. Các sản phẩm đầu cuối và phụ kiện bao gồm: nhiều loại cách điện tổng hợp, cao su silicone, phụ kiện cách điện, phụ kiện dây dẫn và các loại khác. Lõi thủy tinh epoxy mà chúng tôi sản xuất được sử dụng rộng rãi như là bộ nối trung gian và các bộ phận cách điện trong nhiều lĩnh vực và nhiều loại cách điện tổng hợp. Profile và cách điện tổng hợp được sử dụng rộng rãi trong các lĩnh vực điện lực, điện tử, đường sắt điện, xây dựng, ô tô và bảo vệ môi trường. Sản phẩm của THIM được bán rộng rãi ở Bắc Mỹ, Nam Mỹ, châu Phi, châu Á, châu Âu, chẳng hạn như Hoa Kỳ, Kenya, Hàn Quốc, Ấn Độ, Việt Nam, Nga, Đức, Romania và các khu vực khác trên toàn quốc. THIM đang trở thành một nhà cung cấp nổi tiếng trong lĩnh vực sản phẩm cách điện trên toàn cầu.

Câu hỏi 1. Bạn là nhà sản xuất hay công ty thương mại?

A. Nhà sản xuất / Công ty Thương mại

q2. Bạn làm thế nào để đảm bảo chất lượng tốt? A. Chúng tôi sử dụng nguyên liệu thô tốt nhất, và mỗi sản phẩm sẽ phải trải qua một loạt các bài kiểm tra nghiêm ngặt.

Câu hỏi 3. Bạn có chấp nhận sử dụng logo của khách hàng không?

A. Có, chúng tôi có thể cung cấp OEM và ODM

Câu hỏi 4. Tôi có thể đặt hàng một số mẫu để thử nghiệm không? A. Có, tất nhiên rồi.

THIM

Cột cách điện hợp kim áp suất cao là một sản phẩm xuất sắc được thiết kế đặc biệt cho việc sử dụng trong đường dây điện áp cao. Được làm từ vật liệu chất lượng cao đảm bảo độ bền, tin cậy và khả năng chịu lực lâu dài. Thiết kế để chịu được điện áp cao và điều kiện thời tiết khắc nghiệt, khiến nó trở thành lựa chọn hoàn hảo cho các công ty phân phối điện.

Một sản phẩm đổi mới mang lại nhiều lợi thế hơn so với các loại cách điện truyền thống. Đây THIM sản phẩm có trọng lượng nhẹ, giúp dễ dàng lắp đặt và xử lý. Ngoài ra, bộ cách điện kháng được cả tia UV và sự ăn mòn hóa học, đảm bảo rằng nó có thể chịu đựng được điều kiện thời tiết khắc nghiệt và môi trường ăn mòn.

Một trong những tính năng nổi bật nhất là thiết kế của nó. Có cấu trúc độc đáo cho phép cung cấp khả năng cách điện điện tốt hơn ngay cả khi bị tác động bởi điện áp cao. Gồm nhiều lớp vật liệu chất lượng cao làm việc cùng nhau để cung cấp hiệu suất cách điện điện xuất sắc.

Được thiết kế để giảm thiểu nguy cơ phóng điện qua không khí. Phóng điện xảy ra khi dòng điện áp cao di chuyển qua không khí để đến mặt đất, gây ra tia lửa. Điều này có thể rất nguy hiểm vì có thể dẫn đến mất điện và thậm chí là cháy nổ điện. Nó có thiết kế đặc biệt giảm thiểu khả năng xảy ra phóng điện, khiến nó an toàn hơn so với các loại cách điện truyền thống.

Có thể tùy chỉnh cao để đáp ứng các nhu cầu cụ thể của các công ty phân phối điện khác nhau. Có sẵn ở nhiều kích thước và hình dạng khác nhau, và khách hàng có thể chọn loại phù hợp nhất với yêu cầu đặc biệt của họ. Ngoài ra, bộ cách điện có thể được tùy chỉnh để đáp ứng các yêu cầu về điện áp và dòng điện khác nhau.

Đây là dành cho bạn. Mua ngay bây giờ.